Felix Pole was an ambitious employee of the Great Western Railway. Born in 1877, by the age of 27 he was working in...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

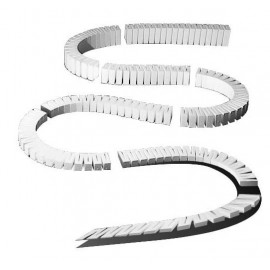

How can I easily create gradient variations for my track?

Creating gradient variations for a model railway track can add realism and interest to a layout. Here are a few ways to create gradient variations easily:

Use inclines: These are small, plastic or foam blocks that can be placed under the track to elevate it. They come in various sizes, allowing a modeller to create a gradual slope. A number of manufacturers produce foam block riser kits. These have the advantage of being light, simple to work with and can be easily cut and shaped to suit a specific layout.

Use ballast: It is possible to use different shades of ballast to create the illusion of a gradient. This can be achieved by mixing different shades of ballast or by using different shades of paint on the ballast to create variations in colour.

Use a rasp or file: A rasp or file can be used to shape the track bed, creating a gradual slope. This method requires some manual labour, but it can give a modeller more control over the gradient.

Use a combination of the above methods: Combining the use of risers, ballast and shaping the track bed can help create a more realistic and varied gradient. It is also worth considering what type of locomotive the layout is intended for. High-speed Passenger Trains work on a gradient of up to 4 degrees on average, whereas slower Freight Train operators prefer as gentle a gradient as possible, rarely exceeding 1.5 degrees.

It is important to keep in mind that creating gradient variations is inevitably a gradual process. It might take several steps and so it is best to adopt a methodical approach and test the gradient before settling on a specific configuration. The gradient should be consistent and if curved should also have minimal camber to keep the track stable and secure to avoid derailing.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.