Felix Pole was an ambitious employee of the Great Western Railway. Born in 1877, by the age of 27 he was working in...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

How can I best care for a razor saw?

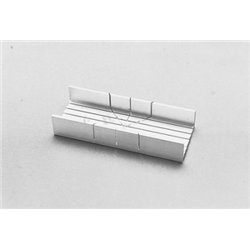

Razor saws are frequently used by modellers for cutting a number of different materials including light woods such as balsa. Inevitably, with continued use, these blades can go dull, so it is important to look after them to aid longevity. One of the first points to note will be the angle of the cut. If not perpendicular to the surface then the cut may be uneven which can induce more wear on the blade. One thing that can help with this is a mitre box, which not only holds the item in question but will also cut cleanly and in a perpendicular fashion as the groves of the box will hold and guide the blade.

When not in use it is a good idea to protect the blade from damage and rust. Ideally, store the blade in a dry location as this will significantly reduce the chances of rust developing. Regularly waxing the teeth of the saw will help protect them by allowing the saw to move easily and more effectively over the surface of the material to be cut. When not in use it is a good idea to coat the blade in a protective oil covering such as WD40. This will significantly reduce the likelihood of rust forming on the blade. Light deposits of rust can be relatively easy to remove with a dremel with a polishing head.

When needed razor saws can be sharpened with a flat file to establish a level base and a diamond file to sharpen the teeth. This can be a time-consuming process, especially on fine razor saws with a high tooth count. In order to save unnecessary wear it is a good idea to have a selection of removable blades with a variety of tooth counts so that the material to be cut can be matched to the appropriate blade. One backup option that might help comes from a most unexpected quarter and could be readily available to hand. Clingfilm and tinfoil dispensers come with an integrated cutting edge to cut the film or foil as required. Inevitably when empty these are discarded but before doing this it may be useful to upcycle the cutting edge to the model toolbox. Although it won't be the most robust of cutting edges it may well suffice for cutting small items or very soft materials with the added benefit that any usage is inevitably aiding in the longevity of razor saw blades.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.