Felix Pole was an ambitious employee of the Great Western Railway. Born in 1877, by the age of 27 he was working in...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

Can a locomotive motor become weaker and lose power over time?

Model locomotives can become weaker over time, but finding the cause is seldom a cut and dry case.

There are many reasons why a model railway locomotive may lose some of its power over time. Unfortunately, no single reason offered here is likely to give you a quick fix to the problem. It's much more likely that a combination of factors contributes to any power loss, especially on older engines.

But to give you an idea, power loss can result from any, or a combination of, five problem areas. These are: conductivity, friction, magnetism, wrong oil and perception.

Starting with perception. This is not so much a problem with the locomotive, but it is a problem nonetheless. Many older locomotives tend to run noisily, suffer dreadfully from coging and seem to lack power. That may not necessarily be the fault of the model. Many locomotives designed and built before the '80s or '90s never ran like the models of today, even when they were new. If such a locomotive in your collection is running badly, a good service and some new brushes will do wonders for its performance, but you should never expect it to run like a brand new modern loco.

Next up is conductivity and friction. These are self-explanatory, if your cogs and bearings are all dried out, corroded or worn, friction will be caused resulting in a loss of tractive effort. If your pickups or electrical connections are of a similar state, your motor cannot draw the current needed to create power. Make sure all conductive components are clean and make good contact. You should also make sure all friction generating components are smooth, free from dirt or corrosion and lightly lubricated.

The next problem area is magnetism. All electric motors used in model railway locomotives require a permanent magnet of some kind for the motor to operate. To be fair, it takes decades for the magnet to lose its magnetism to any great effect, but that process can be greatly accelerated if the motor has ever been stripped down or otherwise interfered with at any time in the past. Having your motor re-magnetised is an option, but generally, cleaning and other maintenance measures should be tried first.

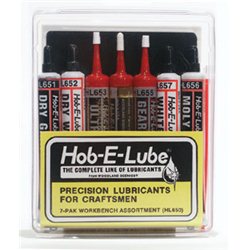

Lastly, the wrong oil can also cause problems. If an oil that is too thick has been used to service the locomotive, the chances are it never penetrated its intended target. Also, if a non-conductive oil was used to lubricate axle bearings which also serve as pickups, conductivity may have been affected. Always use the correct oil for the job to keep locos happy and running correctly.

There are many reasons why a model railway locomotive may lose (or appear to lose) some of its power, but many can be avoided with good maintenance and the use of the correct materials.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.