There are tens of thousands of decals available covering a multitude of different models from trains, planes and...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

How do I fill gaps in a model?

There are a couple of different product types you can use to fill gaps on a model, which type you use will depend on the size of the gap, how much detailing surrounds the gap and finally which filler material you are most comfortable working with.

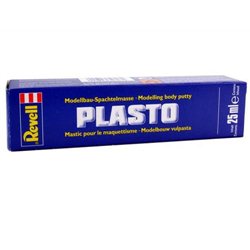

The main types of products used by modellers to fill gaps are putty, water-based fillers and super-glue (cyanoacrylate). For larger gaps, a putty is a good option, it has a consistency similar to modelling clay so is easy to handle, the surplus can be easily scraped away and it will fill larger voids competently. Once it has hardened, putty can be sanded to give a smooth finish, but, as it's a fairly coarse filler it can overwhelm fine detail so care should be taken. Putty fillers are available as two-part epoxies or as a straight forward solvent-based application.

Water-based fillers are ideal for smaller gaps and for working close to finely detailed parts on your model. They have the consistency of toothpaste so can be manipulated into smaller cracks easily. The main advantage of water-based fillers is that any excess material can be wiped away using a damp rag so fine detail that may have been accidentally covered can be saved before the filler has dried.

In some circumstances, cyanoacrylate (super-glue) can also be used to fill smaller cracks. This method is often preferred when a crack doesn't penetrate all the way through a model so there is a danger of air bubbles being trapped or forming when conventional filler is applied. However, some modellers feel that super-glue can create more mess than it's worth, in this instance, a thinned-down water-based filler is a good solution to minimise the risk of bubbles.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.