It can be difficult to accurately estimate how many meters of OO track can be covered with a 250g bag of ballast, as...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

Can I use WD-40 on my model railway locomotive?

Every toolbox has a can of WD-40 in it to rid the world of squeaks and loosen any stubborn nuts and bolts, so the temptation when your model locomotive develops a squeak or starts to run a little rough is to grab the can and get to work. This however would be ill-advised.

There are two main reasons why WD-40 would not be the best tool for the job. Firstly, it's too thick, WD40 is designed for tackling rusty hinges and other heavy-duty tasks, the oil is not suitable for the delicate cogs and shafts within your engine and the chances are it will not penetrate the smaller nooks and crannies that the oil needs to reach.

The second reason why WD-40 is not suitable, is that it's dispensed using a pressurised can spraying thousands of droplets of oil at once. Not forgetting that a model's motor only requires a single drop of oil in specific places, excess oil will get everywhere contaminating and perishing delicate plastics, and even worse, the oil could find its way onto the motor's windings which will fail to perform when covered in a gloopy oil.

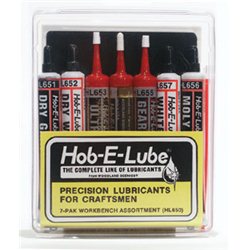

As good as WD-40 is, it's probably best to use a specialised oil and applicator when it comes to your pride and joy.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.