It can be difficult to accurately estimate how many meters of OO track can be covered with a 250g bag of ballast, as...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

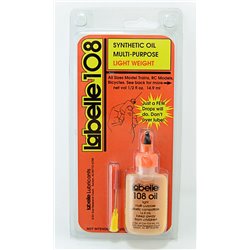

The Dos and Don'ts of Lubricating Your Model Trains

Keeping your model trains running smoothly requires regular maintenance, and lubrication is a key part of that. However, using the wrong lubricant or applying it incorrectly can do more harm than good. To help you keep your layout in top condition, here are the essential dos and don'ts of lubricating your model railway.

The Dos

1. Use the Right Lubricant

Always use a lubricant specifically designed for model railways. Light synthetic oils and plastic-safe greases are ideal. Avoid household oils like WD-40, as they can degrade plastic and attract dust.

2. Apply Sparingly

Less is more when it comes to lubrication. A tiny drop is usually sufficient, as excess lubricant can spread onto tracks, leading to dirt build-up and loss of traction.

3. Lubricate Key Areas

Focus on axle points, gears, and motor bearings. These are the parts that experience the most friction and benefit the most from lubrication.

4. Clean Before Lubricating

Always clean the parts before applying oil or grease. Dust and dirt can mix with the lubricant, creating a grinding paste that will wear down components over time.

5. Check Your Manufacturer’s Guidelines

Every locomotive is different. Some models may have specific lubrication points, and using the wrong type of oil could damage delicate components. Always check the manufacturer's instructions before applying any lubricant.

The Don’ts

1. Don't Over-Lubricate

Excess lubrication can seep into unwanted areas, including electrical contacts, leading to poor conductivity and erratic running.

2. Don't Use the Wrong Type of Oil

Avoid petroleum-based lubricants unless specified, as they can cause plastic parts to degrade. Stick to synthetic, non-corrosive options designed for model railways.

3. Don't Forget the Track and Wheels

Lubrication isn't just about the locomotive. If you notice poor running, check for dirt and oil residue on the wheels and track. Cleaning these regularly can prevent the need for excessive lubrication.

4. Don't Ignore Regular Maintenance

Lubrication should be part of a routine maintenance schedule. Running your trains without checking them periodically can lead to unnecessary wear and tear.

5. Don't Apply Lubricant to the Motor Commutator

The motor’s electrical contacts should remain clean and dry. If lubricant gets onto the commutator, it can cause sparking, overheating, and poor performance.

Final Thoughts

Proper lubrication is essential for keeping your model railway running smoothly and extending the life of your locomotives. By using the right lubricant, applying it sparingly, and following manufacturer guidelines, you can ensure your trains perform at their best for years to come.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.