Felix Pole was an ambitious employee of the Great Western Railway. Born in 1877, by the age of 27 he was working in...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

How do I fix warped plastic parts?

Fixing warped plastic parts on a model can be a bit tricky, but it's a manageable task with some patience and the right approach. Warping often occurs during manufacturing or due to prolonged exposure to heat. To resolve it, you'll need to carefully reshape the part without causing further damage.

The first step is to determine the severity of the warp and the material's thickness. For minor warps, you might be able to gently bend the part back into shape with your hands. However, for more significant distortions, it's best to use controlled heat to soften the plastic, making it pliable enough to adjust without cracking or snapping. Boiling water or a hairdryer set to a low heat are effective options for this.

If you're using boiling water, immerse the warped part in the water for around 10 to 30 seconds. This will soften the plastic without overheating it. Once the plastic becomes flexible, carefully remove it using tweezers or heatproof gloves, and then bend it back into its correct shape. Hold the part in position until it cools and hardens. For a hairdryer, evenly heat the part while gently applying pressure to reshape it.

For particularly delicate or intricate pieces, consider using a jig or a support structure to hold the part in the desired shape while it cools. This can be done by securing the piece to a flat surface or using clamps with padded grips to avoid damaging the plastic. Cooling the part quickly, such as by running it under cold water or placing it in the fridge, will help set the new shape more effectively.

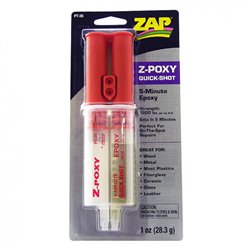

If the warp is too severe to correct entirely, you might need to reinforce the reshaped part. You can use small amounts of super glue or epoxy putty to stabilise any weak points once the piece has been adjusted. Sanding the area lightly after applying these materials will help blend the repair seamlessly.

Always approach warped parts with caution, as too much force or heat can cause irreparable damage. Practising on spare or scrap plastic before working on your actual model can be a good way to build confidence. With the right technique, you can restore warped pieces and ensure your model looks just as it should.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.