Felix Pole was an ambitious employee of the Great Western Railway. Born in 1877, by the age of 27 he was working in...

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search Tips

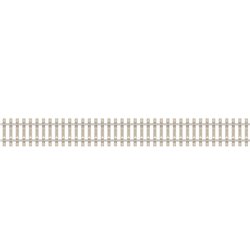

When were concrete sleepers first used on British railways?

Concrete sleepers were introduced to British railways as part of an effort to find more durable and longer-lasting alternatives to wooden sleepers, which were prone to decay and required regular maintenance.

The Southern Railway produced reinforced concrete sleepers at their Exmouth concrete works in 1929 which were laid on the Exeter - Plymouth line, and they remained in use until 1943.

The experimentation with concrete sleepers carried on during World War II, in the early 1940s. This period saw the initial use of concrete sleepers on a trial basis, mainly driven by the scarcity of timber and the need for more resilient railway infrastructure. The wartime conditions necessitated innovation and the use of available resources, pushing engineers to consider concrete as a viable option for railway sleepers.

The post-war era marked a significant shift towards the adoption of concrete sleepers in British railways. During the late 1940s and into the 1950s, the British Transport Commission, which was responsible for overseeing the railways, encouraged the use of concrete sleepers. The post-war reconstruction effort placed a heavy emphasis on rebuilding and modernizing the nation's infrastructure, and concrete sleepers were seen as a way to enhance the durability and longevity of the railway tracks. This period saw increased research and development to improve the design and manufacturing processes of concrete sleepers.

By the 1960s, concrete sleepers had become more widespread on the British rail network. The British Railways Board, established in 1963, continued to promote the use of concrete sleepers as part of its modernization plans. Concrete sleepers offered several advantages over their wooden counterparts, including greater resistance to weathering, pests, and fire. They also provided better stability and support for the rails, contributing to smoother and safer train operations. The adoption of concrete sleepers was further bolstered by advancements in concrete technology, which improved the quality and performance of these sleepers.

The transition to concrete sleepers was not without its challenges. Early designs had to be refined to address issues such as cracking and brittleness. However, continuous improvements in the production techniques and materials used in concrete sleeper manufacturing led to more robust and reliable products. By the latter part of the 20th century, concrete sleepers had become a standard feature on many sections of the British railway network. Their use continued to expand, supported by the development of pre-stressed concrete technology, which enhanced the sleepers' strength and durability. Today, concrete sleepers are an integral part of the UK's railway infrastructure, representing a successful shift towards more sustainable and resilient track components.

Click here to receive the tips weekly in your mailbox. You can unsubscribe at any time.